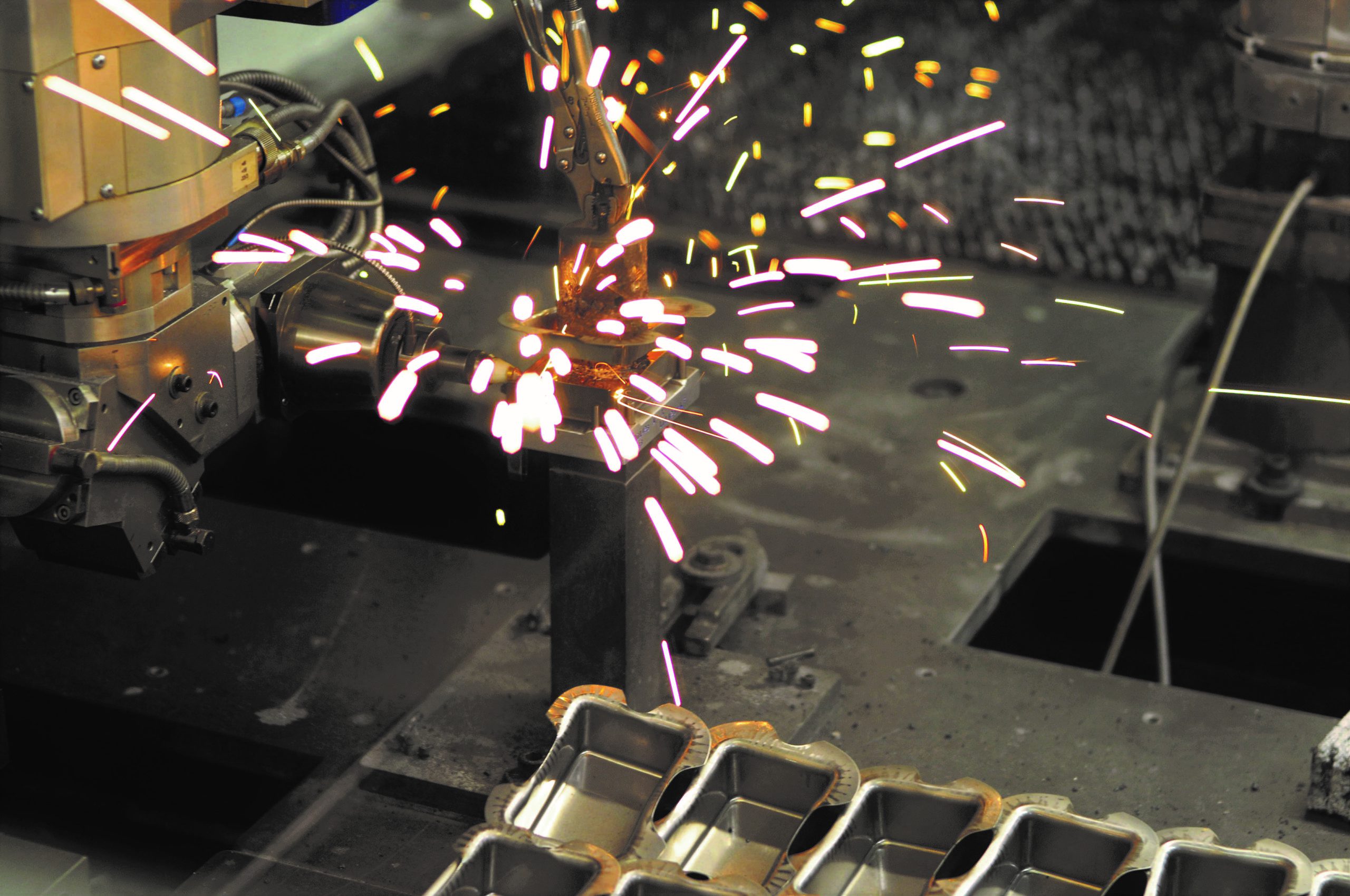

Manufacturing Capabilities

Manufacturing Capabilities

Manufacturing Capabilities

Learn More

Custom Modular Containers

Custom Modular Containers

Custom Modular Containers

Learn More

Custom Transitainer

Custom Transitainer

Custom Transitainer

Learn More

Value Added Services

Value Added Services

Value Added Services

Learn More