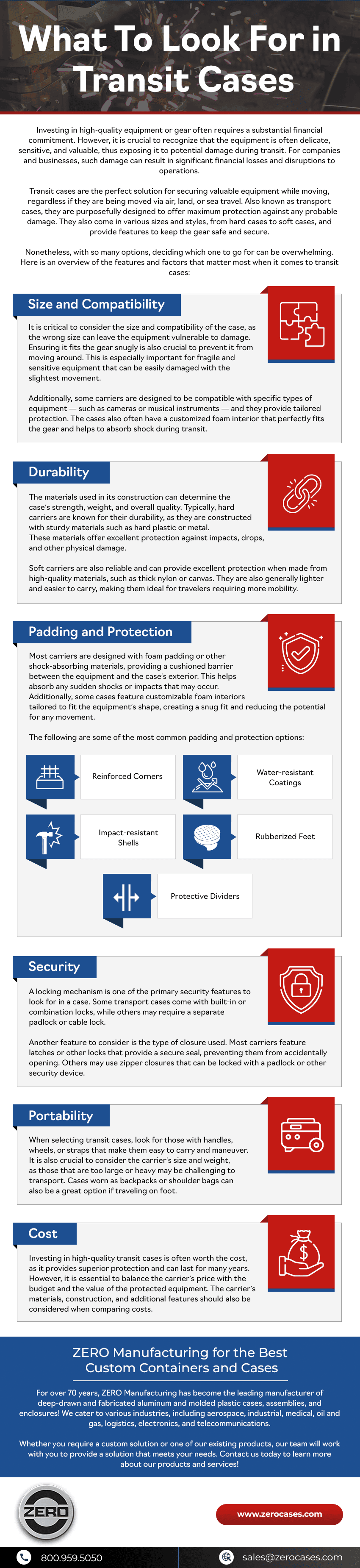

What To Look For in Transit Cases

Leave a CommentInvesting in high-quality equipment or gear often requires a substantial financial commitment. However, it is crucial to recognize that the equipment is often delicate, sensitive, and valuable, thus exposing it to potential damage during transit. For companies and businesses, such damage can result in significant financial losses and disruptions to operations.

Transit cases are the perfect solution for securing valuable equipment while moving, regardless if they are being moved via air, land, or sea travel. Also known as transport cases, they are purposefully designed to offer maximum protection against any probable damage. They also come in various sizes and styles, from hard cases to soft cases, and provide features to keep the gear safe and secure.

Nonetheless, with so many options, deciding which one to go for can be overwhelming. Here is an overview of the features and factors that matter most when it comes to transit cases:

1. Size and Compatibility

It is critical to consider the size and compatibility of the case, as the wrong size can leave the equipment vulnerable to damage. Ensuring it fits the gear snugly is also crucial to prevent it from moving around. This is especially important for fragile and sensitive equipment that can be easily damaged with the slightest movement.

Additionally, some carriers are designed to be compatible with specific types of equipment — such as cameras or musical instruments — and they provide tailored protection. The cases also often have a customized foam interior that perfectly fits the gear and helps to absorb shock during transit.

2. Durability

The materials used in its construction can determine the case’s strength, weight, and overall quality. Typically, hard carriers are known for their durability, as they are constructed with sturdy materials such as hard plastic or metal. These materials offer excellent protection against impacts, drops, and other physical damage.

Soft carriers are also reliable and can provide excellent protection when made from high-quality materials, such as thick nylon or canvas. They are also generally lighter and easier to carry, making them ideal for travelers requiring more mobility.

3. Padding and Protection

Most carriers are designed with foam padding or other shock-absorbing materials, providing a cushioned barrier between the equipment and the case’s exterior. This helps absorb any sudden shocks or impacts that may occur. Additionally, some cases feature customizable foam interiors tailored to fit the equipment’s shape, creating a snug fit and reducing the potential for any movement.

The following are some of the most common padding and protection options:

- Reinforced corners

- Water-resistant coatings

- Impact-resistant shells

- Rubberized feet

- Protective dividers

4. Security

A locking mechanism is one of the primary security features to look for in a case. Some transport cases come with built-in or combination locks, while others may require a separate padlock or cable lock.

Another feature to consider is the type of closure used. Most carriers feature latches or other locks that provide a secure seal, preventing them from accidentally opening. Others may use zipper closures that can be locked with a padlock or other security device.

5. Portability

When selecting transit cases, look for those with handles, wheels, or straps that make them easy to carry and maneuver. It is also crucial to consider the carrier’s size and weight, as those that are too large or heavy may be challenging to transport. Cases worn as backpacks or shoulder bags can also be a great option if traveling on foot.

6. Cost

Investing in high-quality transit cases is often worth the cost, as it provides superior protection and can last for many years. However, it is essential to balance the carrier’s price with the budget and the value of the protected equipment. The carrier’s materials, construction, and additional features should also be considered when comparing costs.

ZERO Manufacturing for the Best Custom Containers and Cases

For over 70 years, ZERO Manufacturing has become the leading manufacturer of deep-drawn and fabricated aluminum and molded plastic cases, assemblies, and enclosures! We cater to various industries, including aerospace, industrial, medical, oil and gas, logistics, electronics, and telecommunications.

Whether you require a custom solution or one of our existing products, our team will work with you to provide a solution that meets your needs. Contact us today to learn more about our products and services!