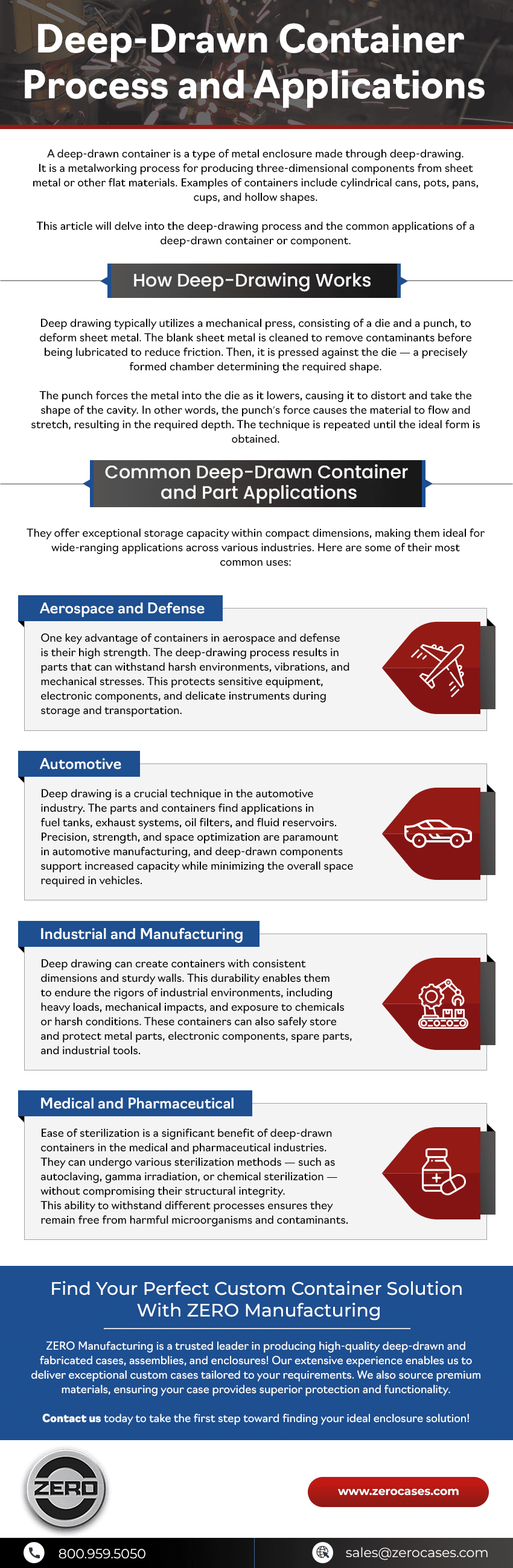

Deep-Drawn Container Process and Applications

Leave a CommentA deep-drawn container is a type of metal enclosure made through deep-drawing. It is a metalworking process for producing three-dimensional components from sheet metal or other flat materials. Examples of containers include cylindrical cans, pots, pans, cups, and hollow shapes.

This article will delve into the deep-drawing process and the common applications of a deep-drawn container or component.

How Deep-Drawing Works

Deep drawing typically utilizes a mechanical press, consisting of a die and a punch, to deform sheet metal. The blank sheet metal is cleaned to remove contaminants before being lubricated to reduce friction. Then, it is pressed against the die — a precisely formed chamber determining the required shape.

The punch forces the metal into the die as it lowers, causing it to distort and take the shape of the cavity. In other words, the punch’s force causes the material to flow and stretch, resulting in the required depth. The technique is repeated until the ideal form is obtained.

Common Deep-Drawn Container and Part Applications

They offer exceptional storage capacity within compact dimensions, making them ideal for wide-ranging applications across various industries. Here are some of their most common uses:

Aerospace and Defense

One key advantage of containers in aerospace and defense is their high strength. The deep-drawing process results in parts that can withstand harsh environments, vibrations, and mechanical stresses. This protects sensitive equipment, electronic components, and delicate instruments during storage and transportation.

Automotive

Deep drawing is a crucial technique in the automotive industry. The parts and containers find applications in fuel tanks, exhaust systems, oil filters, and fluid reservoirs. Precision, strength, and space optimization are paramount in automotive manufacturing, and deep-drawn components support increased capacity while minimizing the overall space required in vehicles.

Industrial and Manufacturing

Deep drawing can create containers with consistent dimensions and sturdy walls. This durability enables them to endure the rigors of industrial environments, including heavy loads, mechanical impacts, and exposure to chemicals or harsh conditions. These containers can also safely store and protect metal parts, electronic components, spare parts, and industrial tools.

Medical and Pharmaceutical

Ease of sterilization is a significant benefit of deep-drawn containers in the medical and pharmaceutical industries. They can undergo various sterilization methods — such as autoclaving, gamma irradiation, or chemical sterilization — without compromising their structural integrity. This ability to withstand different processes ensures they remain free from harmful microorganisms and contaminants.

Find Your Perfect Custom Container Solution With ZERO Manufacturing

ZERO Manufacturing is a trusted leader in producing high-quality deep-drawn and fabricated cases, assemblies, and enclosures! Our extensive experience enables us to deliver exceptional custom cases tailored to your requirements. We also source premium materials, ensuring your case provides superior protection and functionality.

Contact us today to take the first step toward finding your ideal enclosure solution!

How To Get the Right Modular Containers

Leave a CommentModular containers are standardized in size and shape, enabling easy transportation and assembly. These containers have also gained popularity in various industries due to their cost-effectiveness, versatility, and ease of use. They are often used in aerospace, military and defense, industrial, and oil and gas.

The most common use of these containers is in the shipping industry. Standardized freight containers are used to transport goods across different modes of transportation, including ships, trains, and trucks.

However, it is important to note that not all containers are designed equal. Several factors can differentiate them, including size and configuration,insulation and climate control features, and customization options. This article will examine each aspect to ensure the container performs its intended function effectively.

Factors To Consider During Container Selection

Selecting the right container is a crucial decision that can significantly impact the success and efficiency of the project or application. The following are some of the most important considerations during the container selection process:

1. Size and Configuration

Modular containers come in various sizes.20-foot and 40-foot containers are standard options, and custom sizes are available to cater to specific requirements. Given the options, it is essential to evaluate the available space, transportability, and intended application to determine the appropriate dimensions.Additionally, potential expansion or scalability requirements must be identified.

The configuration refers to the layout, design, and placement of doors, windows, and partitions. Evaluating how these elements align with the project’s functional requirements is crucial. For instance, containers with multiple entry points and strategically located windows can improve accessibility, natural lighting, and ventilation.

2. Construction Materials

The construction materials of a modular container play a significant role in its durability, strength, and overall performance. Here is an overview of the importance of construction materials in container selection:

Aluminum

Our modular containers at ZERO Manufacturing are designed with a unique construction that minimizes weight while maintaining exceptional strength. This strength-to-weight ratio ensures maximum protection for cargo, all while minimizing transport costs. In fact, the savings in cargo and shipping expenses alone can often offset the container’s initial cost, making it a cost-effective choice in the long run.

Coatings and Treatments

Some containers feature additional coatings or treatments to enhance their durability and performance. These may include anti-corrosion treatments, such as zinc coatings or epoxy paints, that provide an extra layer of protection against rust and corrosion.

3. Insulation and Climate Control Features

Insulation regulates the internal temperature of a container, preventing heat gain in hot climates and heat loss in frigid climates.

In addition, climate control systems can be installed to further regulate the interior environment. These include HVAC systems, fans, ventilation, and heating and Cooling units

4. Mobility

The containers are designed to be portable and easily transported. Typically, they have corner castings and twist-lock mechanisms that enable safe layering and interlocking during transport. This allows for efficient loading and unloading onto vehicles, ships, and trains, making them ideal for logistics and shipping applications.

5. Customization Options

Customization options allow the tailoring of the container to specific needs and optimize its functionality. For instance, door and window configurations can be modified to improve accessibility and ventilation. Optional features may also include strategically located sliding doors, roll-up doors, and extra windows. ZERO Manufacturings customization options include the following:

- Drop and vibration protection systems

- Wheels and rollers

- Custom hardware

- Humidity indicators

- Multiple finishing options (epoxy primer, glossy paint, lusterless paint, camouflage paint, anti-glare finish)

- Chem Film

- Marking options (silk screening, stenciling, engraving, labeling)

- Top opening, pallet and shroud, split, or double-ended

- Clean room environment

Discover the Best Custom Containers and Cases at ZERO Manufacturing

ZERO Manufacturing has over 70 years of experience manufacturing top-notch deep-drawn and fabricated cases, assemblies, and enclosures for diverse industries.Our expertise allows us to deliver custom cases tailored to your requirements, ensuring they align with your budget and timeline. We also utilize advanced manufacturing techniques, state-of-the-art equipment, and premium materials.

Contact us today, and our team will collaborate with you to identify the ideal enclosure solution!